Mid-State Litho: Your Premium Equipment Distributor

Welcome to Mid-State Litho, your reliable partner for comprehensive printing industry support. As specialists in the field, we offer an extensive selection of machinery ranging from paper folders and guillotine paper cutters to bookletmakers, perfect binders, paper creasers, and more. Our well-rounded inventory serves to empower your printing operations, enhancing efficiency and product quality.

In our capacity as print and print-finishing experts, we relish taking on complex challenges. Our product offerings are designed to cater to a wide array of applications. This includes solutions for lower-volume operations like office environments that require routine handling of invoices or similar tasks. Our collection features an assortment of compact machines, accommodating a spectrum of budgetary needs.

40 Years in Business

Our company is commemorating its 40th year in business, underlining our commitment to delivering exceptional service to our valued customers. Our distinctive strength lies in the robust technical support and dedicated after-sales service that we provide. We believe that in the high-stakes world of production, reliability is paramount. To meet tight deadlines and demanding applications, you need dependable equipment that is supported by unparalleled service.

Here at Mid-State Litho, we are committed to supplying you with top-tier production equipment and services, each backed by our decades-long tenure in the print industry. We are grateful for the opportunity to serve as your trusted partner in all matters related to print, paper folding, and booklet making. Thank you for choosing Mid-State Litho.

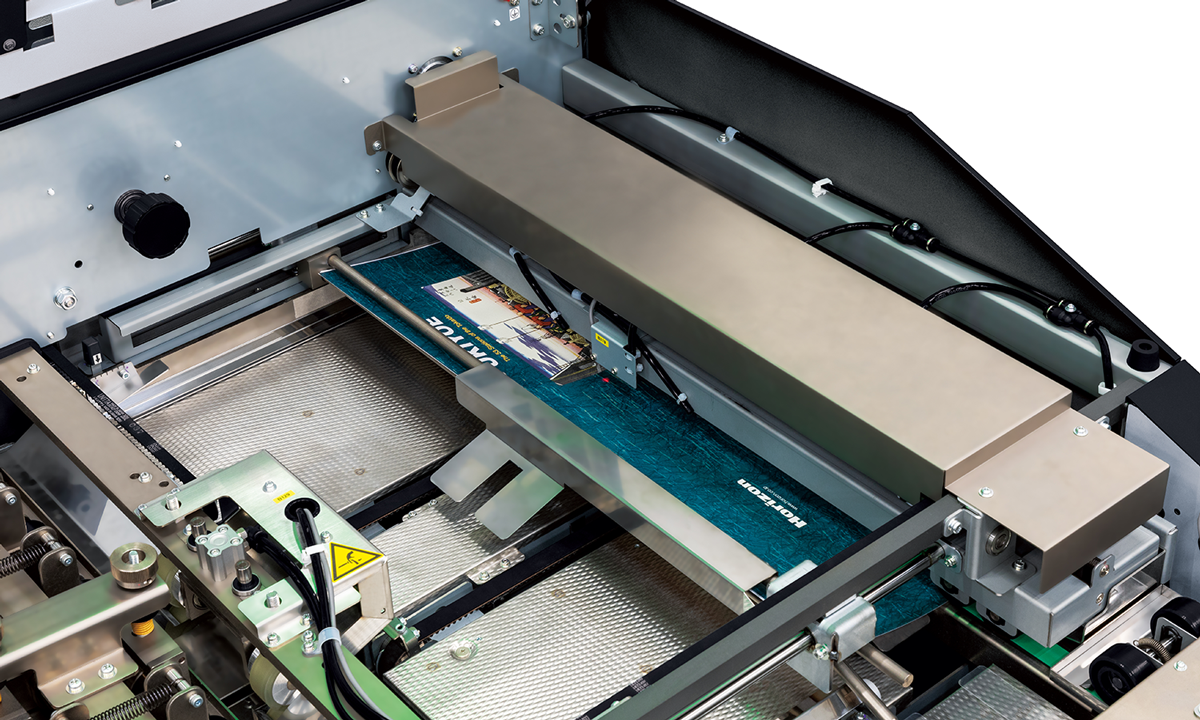

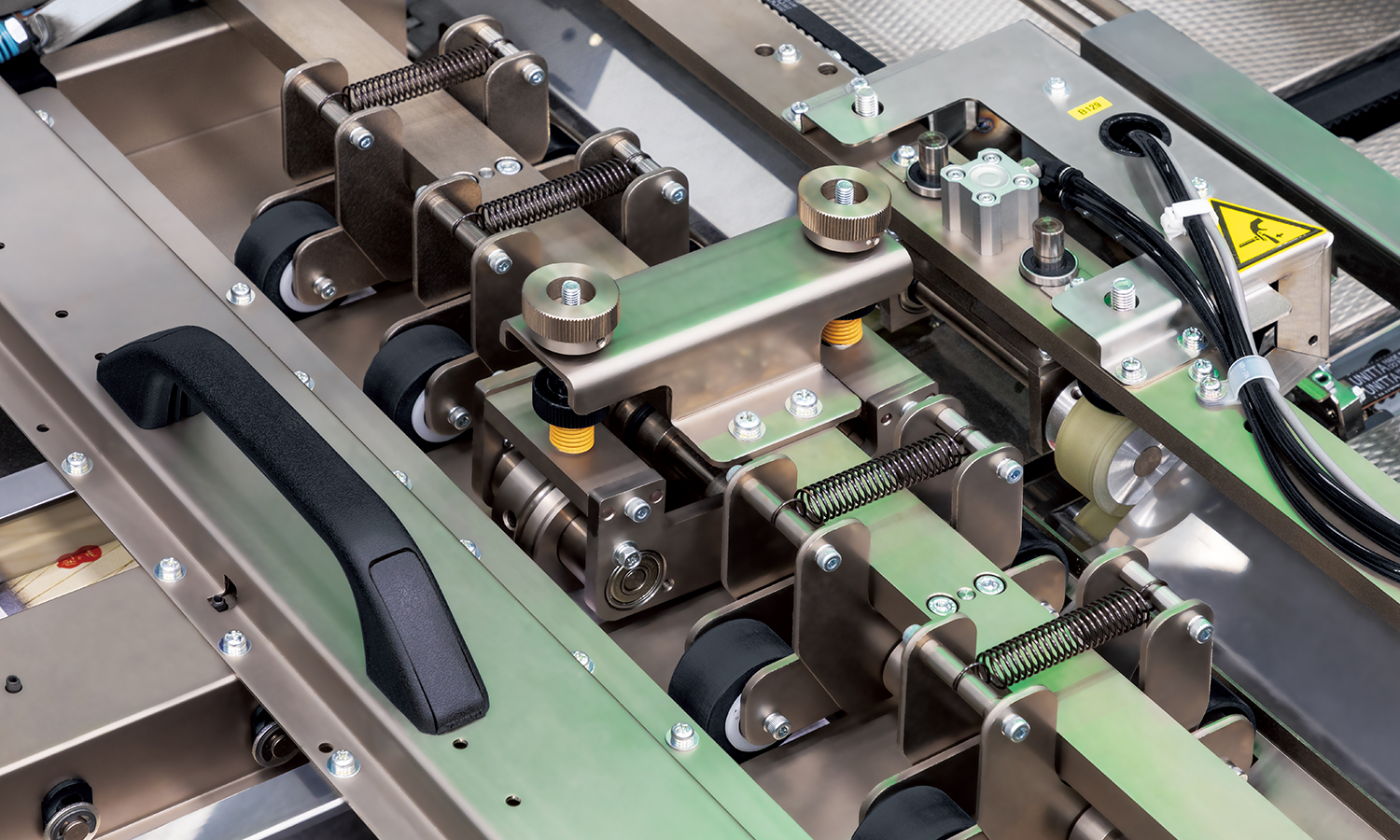

Horizon BQ-500 Perfect Binder iCE LiNK

The BQ-500 perfect binder is designed for all new production levels. Yet it keeps the same great level of quality as the predecessor. The first perfect binder to come equipped with iCE LiNK, Horizon's new cloud-based JDF workflow and job-management tool.

Check for quick and easy answers

Frequently Asked Questions

What is perfect binding?

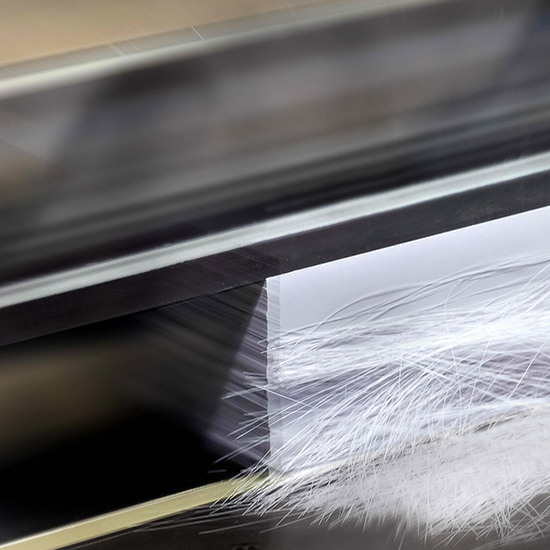

Perfect binding is a method of manufacturing books using hot glue. Sometimes called thermal binding, it has a few steps. First is spine preparation with a milling or notching blade. Then the glue is applied and a book cover is pressed on with a tremendous amount of pressure. This process is called nipping.

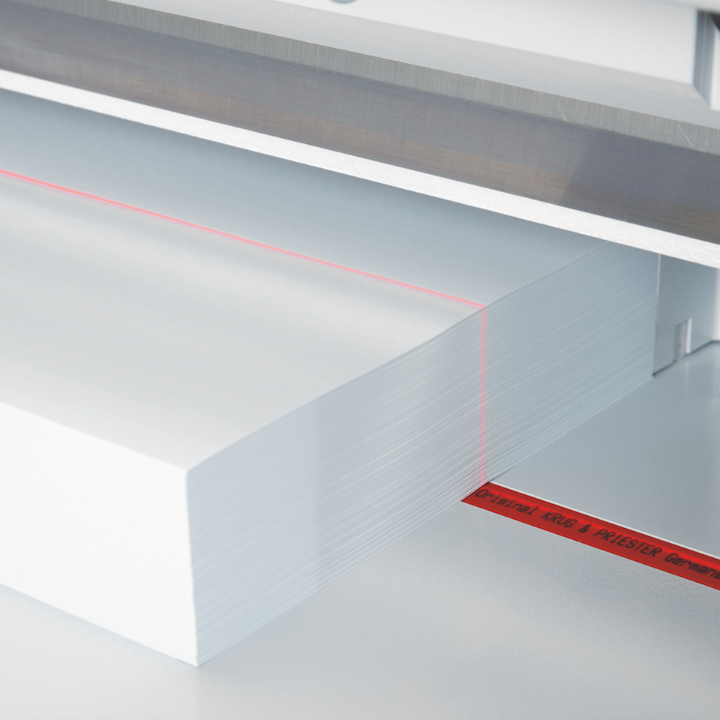

What size paper cutter should I get?

The width of the cutter is the maximum cut you can make. So if you only ever need to cut 18" sheets then you could get away with a 18" cutter. However, the general guideline is that you want to be able to spin your largest sheet under the knife. So for a 12x18 sheet the calculated diagonal gives us the the minimum cutter width of 21.6."

What kind of paper folder should I get?

This is a great starting point! The first consideration would be if you can use a tabletop folder. Tabletop folders work great for most office environments. They almost always have 2 fold plates so you can do letter folds and C or Z folds. Next consider your paper type. If you fold glossy or coated paper you should get a folder with an air feeder. If you are folding for profit you should consider a larger air folder with a pump.

Do you offer financing?

Yes! Mitsubishi HC Capital is our primary leasing partner. We can offer short- or long-term financing based on your needs. Financing is subject to credit approval but our team is excellent. If you are considering financing your purchase you can visit our financing page or contact us directly.

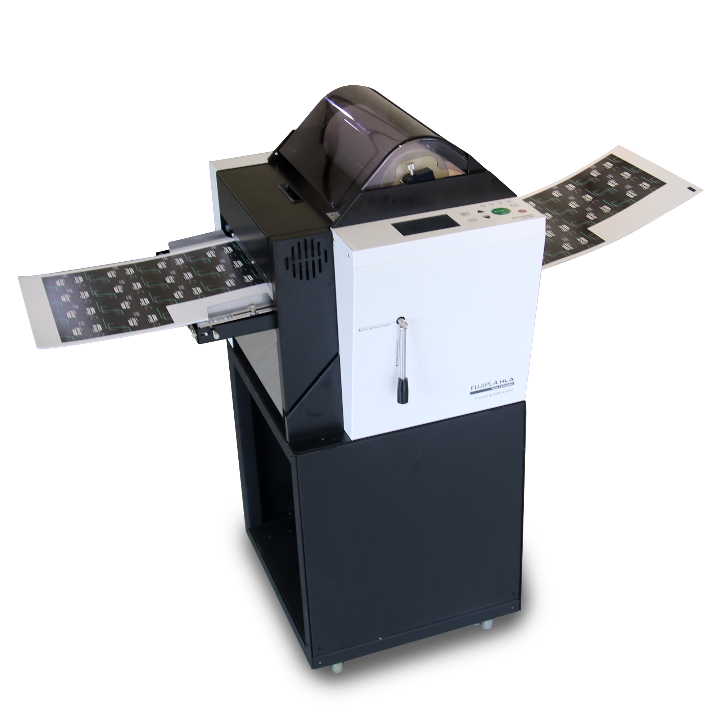

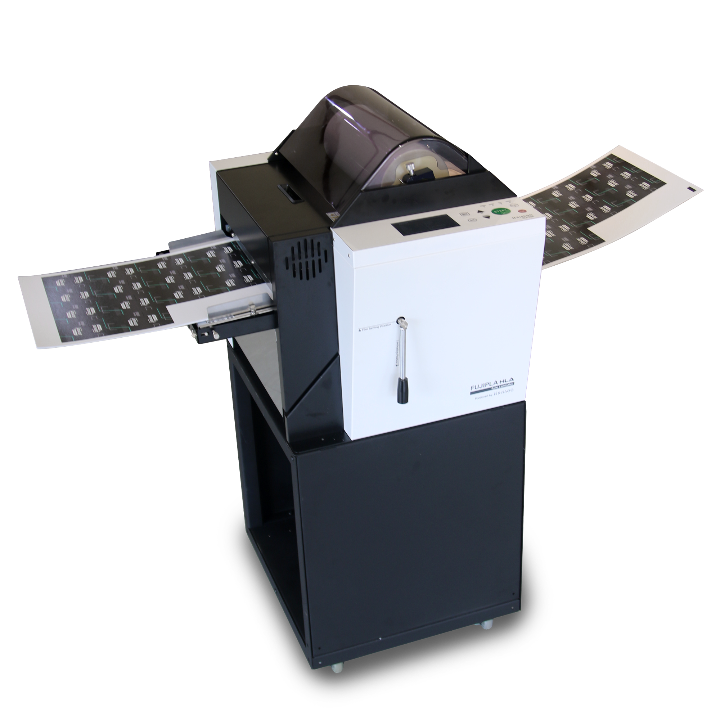

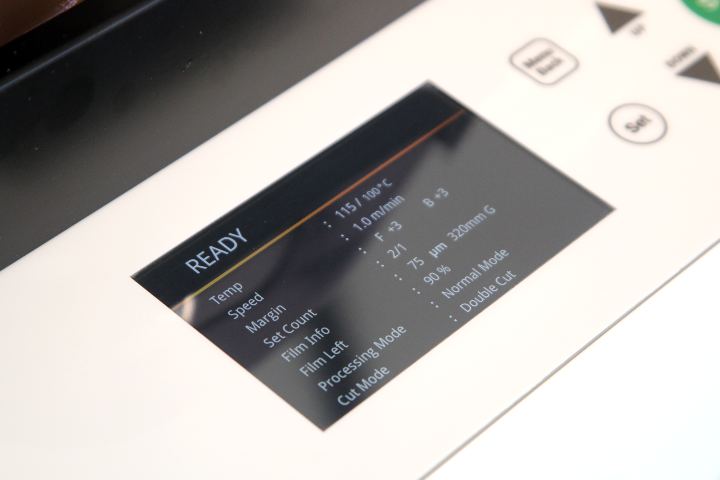

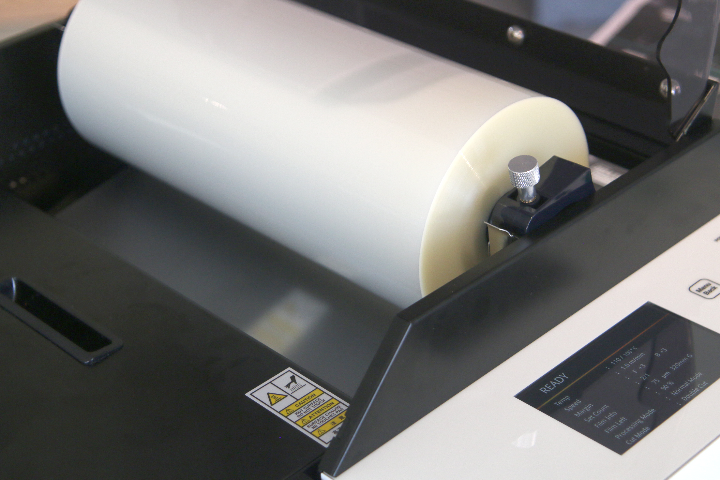

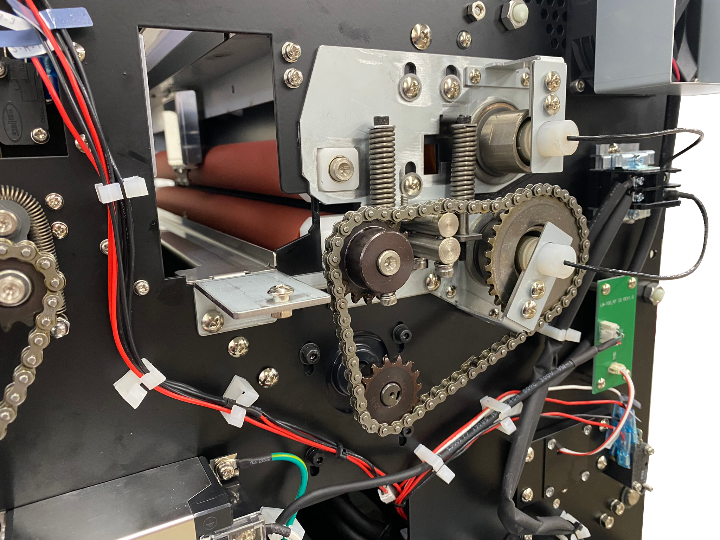

DryLam

Dry-Lam HLA-2301 Automatic Laminator

Share

AccurioPress C6085 Digital Color Press

Get ready for a game-changer. The AccurioPress C6085 Digital Color Press from Konica Minolta is revolutionizing production print and establishing new standards for cut-sheet digital presses. The C6100/C6085 performs, print after print, run after run, job after job, on diverse media such as envelopes, weights up to 400 gsm and sizes up to 47-inch banners.

Postmark

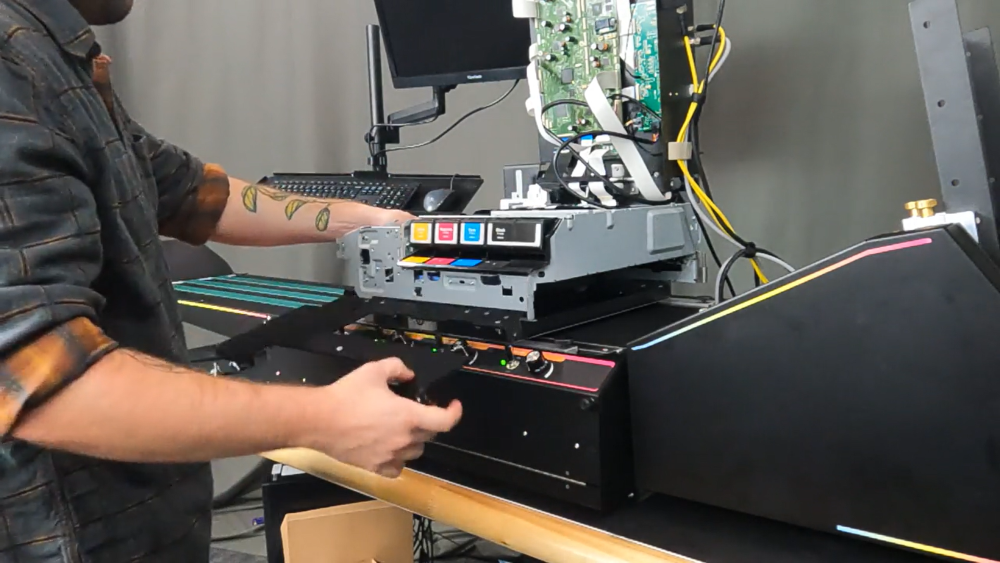

1170 Rapidcolor Core Color Inkjet Printer

Share

The 1170 RapidColor Core Color Inkjet Printer, designed by Postmark, is the perfect choice for those seeking a professional and versatile printing solution. Whether you need to print on envelopes, shopping bags, cardboard boxes, napkins, or more, the 1170 RapidColor Print Solutions deliver exceptional high-speed, four-color printing with outstanding quality.

View full details

Standard Horizon

Horizon PF-P3110 Paper Folder

Share

MBM

MBM Triumph 5260 Paper Cutter (20-3/8")

Share

Triumph paper cutters are manufactured in Germany. They feature an electric drive system. Models are available with safety light curtains or a plexiglass tilt-shield for even more savings.

View full details

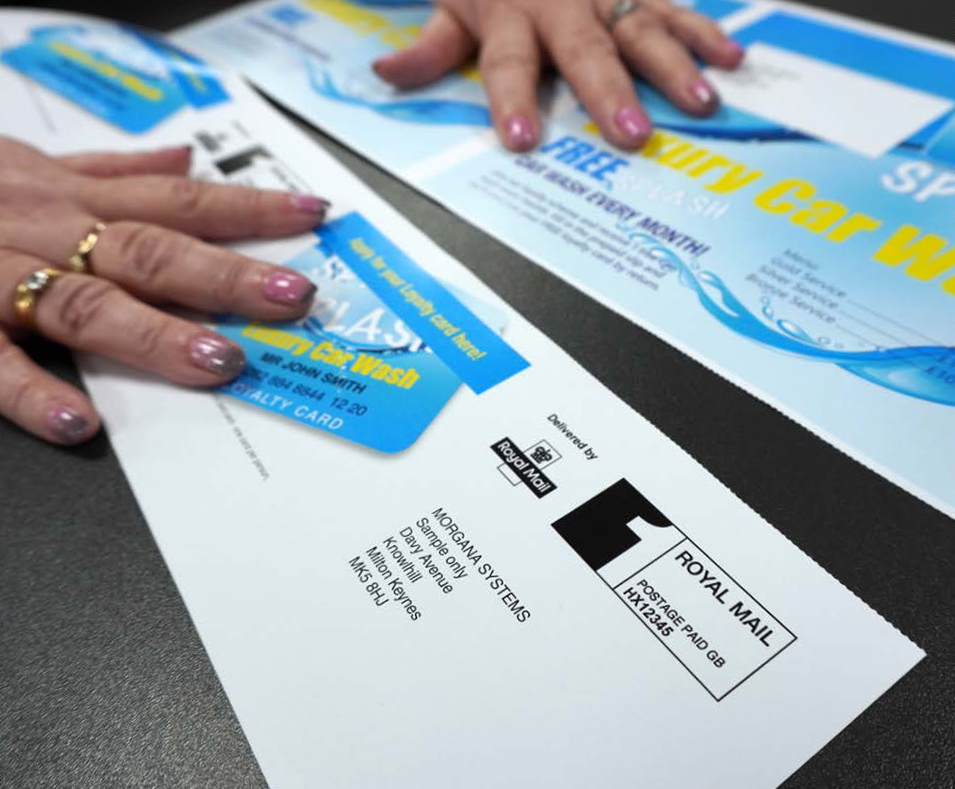

Postmark

Postmark EnveJet Envelope Printer - All-in-One Solution for High-Speed, Full-Color Envelope Printing

Share

The EnveJet envelope printer is the ultimate all-in-one solution for businesses seeking high-speed, full-color envelope printing. With its streamlined design and advanced features, this printer offers unparalleled efficiency and versatility.

View full details

MSL

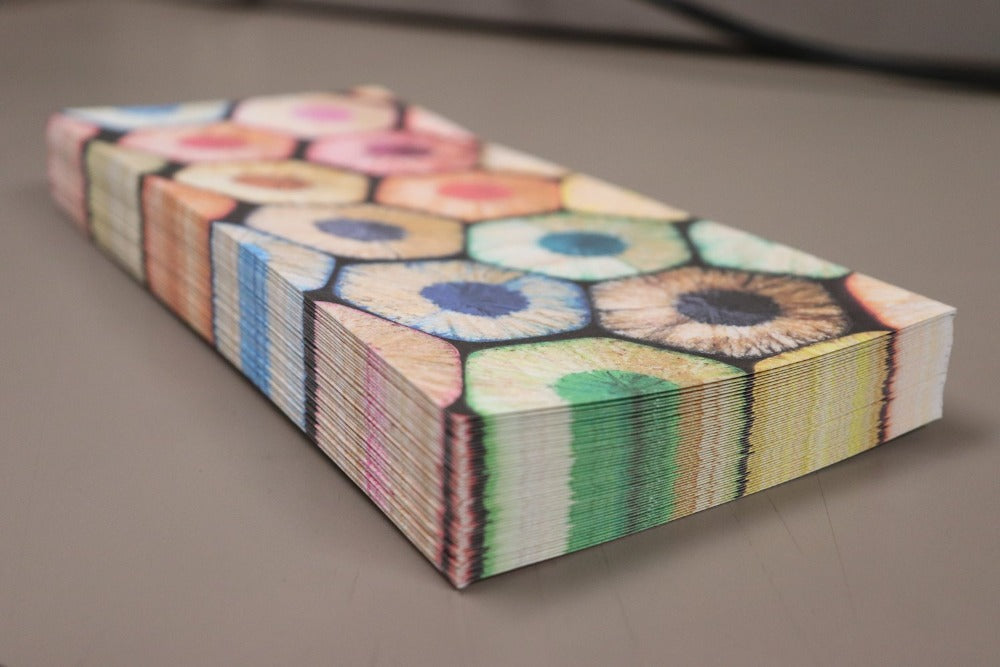

Durable 25 Gauge Nickel Plated Stitcher Wire for Book Production

Share

Favorite Collections

Martin Yale Desktop Paper Folders

Browse the great collection of paper folders, paper creasers, joggers, and more from one of our favorite manufacturers, Martin Yale. Their products are made here in the USA in Wabash, Indiana.

-

Martin Yale 2051 Smartfold Electronic Paper Folder with Automatic Feeder and Variable Speed

Regular price $3,575.59 USDRegular priceUnit price per -

Martin Yale P6500 Desktop Paper Folding Machine

Regular price $295.00 USDRegular priceUnit price per -

Martin Yale 1812 AutoFolder Paper Folder

Regular price $3,210.00 USDRegular priceUnit price per -

1217A Autofolder 12" X 18" Paper Folder

Regular price $1,786.00 USDRegular priceUnit price per

Enough About Us...

Let's figure out your project. Whether it's something completely new or expanding a production line you already have; we're here to help. Contact our sales team for some consultation or browse all of our products to help brainstorm some new idea.